Product Structure Design & Common Surface Treatment Processes

Effective Product Structure Design encompasses not only the physical form and assembly of components but also critically considers the surface treatment processes that enhance aesthetics, functionality, and durability. Choosing the right finishing technique is integral to realizing the design intent and ensuring product success. Below is an overview of several common surface treatment processes vital to product design.

Spray Painting Process in Product Finishing

Definition: Spray painting, also known as spraying or coating, is a process that evenly applies paint (e.g., acrylic paint, PU paint, UV paint) onto product surfaces using a spray gun.

Common Applications: Plastic parts (e.g., toys, appliance housings, phone cases); Metal parts (e.g., hardware tool housings); Wood products (e.g., furniture, crafts).

Purpose:

-

Enhance appearance: Alter color, add gloss or matte effects.

-

Protection: Waterproofing, moisture resistance, corrosion prevention.

-

Functionality: Special coatings for slip resistance, wear resistance, anti-fingerprint, etc.

Baking Paint Process for Durable Product Design

Definition: Baking paint = Spray painting + High-temperature baking. After spraying, workpieces are cured in a baking oven at specific temperatures (typically 60°C–180°C).

Common Applications: Automotive exteriors (auto baking paint); Furniture (baked-paint cabinets, tabletops); Electronics housings (e.g., speakers, monitors); Home appliances (baked-paint refrigerators).

Typical Process:

-

Grinding: Ensures a smooth, impurity-free surface.

-

Primer spraying: Enhances adhesion.

-

Intermediate grinding: Ensures uniform layer bonding.

-

Topcoat spraying: Determines final color and effect.

-

Baking curing: High-temperature heating in an oven to form a paint film.

Screen Printing Process in Industrial Applications

Definition: Screen printing (abbreviated as “screen printing”) transfers ink to surfaces using a mesh stencil. A squeegee forces ink through the mesh pores, imprinting patterns onto substrates.

Common Applications: PCB character printing; Mobile glass cover icons; Button patterns/control panel text; Industrial equipment logos, functional markings, panel graphics.

Advantages:

-

Versatility: Applicable to plastics, metals, glass, ceramics, wood, etc.

-

Durability: Strong ink adhesion, fade-resistant.

-

Process stability.

Pad Printing Process for Complex Shapes

Definition: Pad printing uses a silicone pad to pick up patterns from an etched steel plate and transfer them onto target objects.

Common Applications: Numbers/functional symbols on buttons; Logos on cosmetic caps; Decorative patterns (e.g., eyes on toys).

Advantages:

-

Shape adaptability: Prints on spheres, curves, concave surfaces, etc.

-

High precision: Reproduces fine lines, small text, and icons.

-

Cost-effective: Ideal for small-area or monochrome prints.

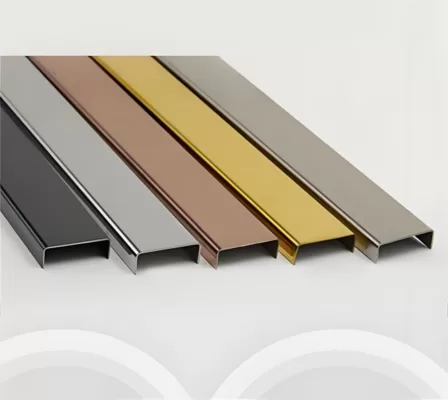

Electroplating Process for Aesthetics & Corrosion Resistance

Definition: Electroplating deposits a layer of metal/alloy onto surfaces via electrolysis (e.g., nickel, chromium, gold, silver).

Common Applications:

-

3C digital products: Smartphone frames, earphone housings, laptop trims.

-

Automotive parts: Logos, trim strips, lamp reflectors, interior buttons.

Advantages: -

Enhanced aesthetics: Achieves metallic luster, mirror, matte, pearlescent, or gunmetal grey finishes.

-

Corrosion resistance: Prevents metal rust or plastic aging.

Integrating Surface Treatments in Product Structure Design

Tthe selection and integration of appropriate surface treatment processes like spray painting, baking paint, screen printing, pad printing, and electroplating are fundamental aspects of successful Surface Treatment Processes. These processes directly impact the final product’s visual appeal, tactile feel, protective qualities, and brand perception. Understanding their capabilities, limitations, and applications allows designers to make informed decisions that bridge the gap between conceptual design and manufacturable, high-quality end products. Ultimately, mastering these finishing techniques is key to achieving both the functional goals and aesthetic vision inherent in robust Surface Treatment Processes.