Metal Surface Treatment Processes, including sandblasting, brushing, laser engraving, etching, electroplating, electrophoresis, among others.

1. Sandblasting

Using compressed air as the power source, a high-speed jet stream propels abrasive materials (copper slag, quartz sand, emery, iron grit, sea sand) onto the work piece surface, altering its appearance or shape.

2. Brushing

Employing reciprocating abrasive cloth strips, the workpiece surface is repeatedly rubbed to enhance smoothness, forming a straight-line grain pattern. This process improves surface quality and conceals minor scratches.

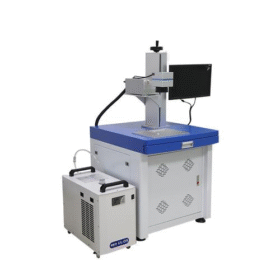

3. Laser Engraving

Based on CNC technology with laser as the processing medium, materials undergo instantaneous melting and vaporization under laser irradiation. This physical transformation achieves precise engraving objectives.

4. Etching

Through exposure plate-making and developing, the protective film is removed from targeted areas. Contact with chemical solutions dissolves and corrodes the exposed material, creating raised/recessed or hollowed effects.

5. Electroplating

Utilizing electrolytic principles, a metal coating is deposited onto substrates (metal or other materials). This prevents oxidation while improving wear resistance, conductivity, reflectivity, corrosion resistance, and aesthetics.

Upload Image...

6. Electrophoresis

Refers to the phenomenon where charged particles migrate toward oppositely charged electrodes under an electric field. Industrial applications leverage differential particle migration speeds for separation/coating processes.

Metal Surface Treatment Processes a suite of advanced techniques engineered to enhance the functional and aesthetic properties of metallic substrates.