9-Aluminum Cabinet Profile

Hole Spacing Handle

Aluminum Handles

Aluminum Handles

Aluminum Handles

9-Aluminum Cabinet Profile

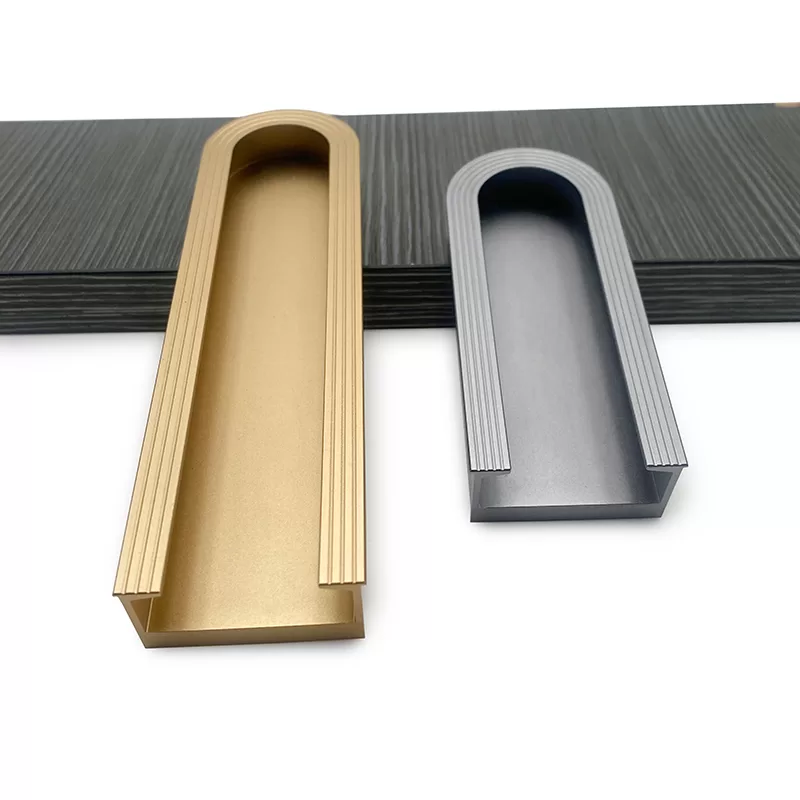

Recessed Concave Aluminum Pulls – Hidden Handle Profile for Kitchen Cabinets

Handle advantages

Lightweight and high-strength Lightweight and Durable: Aluminum alloy has a low density (approximately 1/3 that of steel), but through alloy reinforcement and structural design, its strength approaches that of steel, making it resistant to deformation after installation.

Strong corrosion resistance Antioxidant and rustproof: Forms a dense oxide film on the surface, naturally resistant to corrosion, suitable for humid environments (such as kitchens and bathrooms).

Strong adaptability: capable of withstanding acidic and alkaline environments with a long service life.

Diverse surface treatments with high aesthetic appeal Rich in craftsmanship: Capable of undergoing treatments such as anodization, spraying, electrophoresis, and wood grain transfer, with a wide range of colors (metallic, black, gold, etc.). Premium Texture: Suitable for modern, industrial, minimalist, and various other decor styles.

Easy to process and customize Good plasticity: easy to extrude and shape, capable of manufacturing complex cross-sections or curved designs.

Flexible customization: supports personalized size, shape, and surface texture customization.

How to Install Furniture Accessories

Measure the thickness

Select suitable self tapping screws. Generally, screws should be 3-5mm shorter than wooden boards

Measurement of hole spacing

Based on the hole position on the handle, reserve the hole position on the cabinet door in advance. Common hole spacing includes 32/64/96/128/160/192/224mm

Preparation tools

Generally, electric drilling machines are used to complete the operation. Choose the appropriate drill bit size, usually 1-2mm smaller than the diameter of the screw rod.

Pre installation test

If multiple handles are installed, it is recommended to first install a complete one as a sample, confirm that it is correct, and then use it as a standard for batch installation of others.

For embedded handles

Before installation, measure the bottom dimensions and slot in advance.

For long handles

Before installation, it should be confirmed that their opening and closing with the edge of the door panel and adjacent cabinet doors are not affected.

Perform deep processing aluminum handles

Design and mold making

We have over 2000 molds available for customers to choose from - the basis for determining the final shape of the handle. Also we could accept customization.

Material selection

We will choose aluminum alloy 6063-T5, which combines strength with good corrosion resistance and processability. Multiple surface treatments can also be done.

CNC machining

Complete drilling, tapping, and milling steps to meet all customized needs of customers.

Deburring and polishing

Use manual or automated equipment to remove all sharp edges and burrs generated by machining, making the handle edge smooth without cutting the hand. This is an important process to ensure the tactile sensation.

aluminum handle accessories Features

A Series: Arched design with safety chamfer, solid handle with thick quality, The hole spacing can be customized arbitrarily, and the use of screws can facilitate installation.

C Series: Embedded design, flush with your cabinet door, more suitable for your minimalist design style. It needs to be slotted in advance, no need to install with screws, just fix with nail free aglue.

D Series: The right angled design makes the handle more in line with artificial mechanics, making it more convenient for us to pull and use in daily life.

E Series: The arched bending design and integrated handle make your cabinet and handle seamlessly integrated.The hole spacing can be customized arbitrarily, and the use of screws can facilitate installation.

F Series: Various types of milling designs to meet customers' customized needs for handle shapes.The hole spacing can be customized arbitrarily, and the use of screws can facilitate installation.

9 Series: The vertical and horizontal embedded design makes your cabinet more space saving. Pre slotting is required to prepare for installation and adapt to cabinet board thicknesses of 16-25 models.

Aluminum handle application scenarios

Cabinets and wardrobes

Modern cabinets and wardrobes often use aluminum handles for drawers and door panels. The simple lines and metallic texture can enhance the overall design sense (commonly seen in minimalist, Nordic, and industrial styles)

Office furniture

Filing cabinets, drawers, storage cabinets, etc., with durable aluminum handles that meet the practical needs of the office environment.

Customized furniture

Aluminum can be anodized into various colors (such as black, silver, gold, matte, etc.), suitable for personalized customized design.

Sliding doors/windows

Used for balcony doors, shower rooms, wardrobe sliding doors, etc. The aluminum handle and aluminum alloy frame have a unified style and are rust and corrosion resistant.

Frequently Asked Questions

Of course, we can provide printing and laser engraving methods

Sure, our products have passed a 72 hour salt spray test and are corrosion-resistant.

Yes, we accept customized anodized colors. Silver and black can be customized up to 6m in length, while other colors are 3m in length.

We have CNC machines of different sizes and can accept customized CNC machines up to 6m in size.

The link at the bottom of the webpage allows you to directly contact our WhatsApp and email. Samples can be sent out on the same day at the earliest, and drawings can also be sent for price evaluation.

Production time will take 2-4 weeks usually. If for large quantity, the longest will not exceed 45 days.