Aluminum Alloy Handles – Durable & Stylish for Modern Homes

In home decoration, hardware accessories may seem insignificant, but they directly affect the user experience and overall aesthetic of furniture. As a frequently used hardware item, aluminum alloy handles require a balance of practicality and decorativeness in selection. From material characteristics to style matching, mastering these core points will help you choose aluminum alloy handles that are both durable and beautiful.

Material Performance – Strength & Corrosion Resistance of Aluminum Handles

Aluminum alloy has become the mainstream material for handles due to its unique physical properties. High-quality aluminum alloy handles are made of high-purity aluminum-magnesium alloy, formed through CNC die-casting technology, featuring high strength and light weight. Their load-bearing capacity can reach over 30 kilograms, ensuring they won’t deform or break during daily door and cabinet opening and closing. Meanwhile, aluminum alloy naturally offers corrosion resistance and oxidation resistance. After surface treatment, even when used in humid environments like kitchens and bathrooms, it can effectively resist moisture erosion, preventing rust and discoloration, with a service life of over 10 years.

Surface Treatment – Enhancing Texture & Longevity

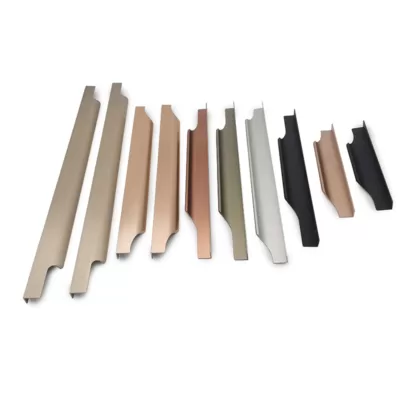

Surface treatment processes directly determine the texture and durability of handles. Common processes for aluminum alloy handles include:

1.Anodizing: Forms an oxide film on the surface, with a delicate touch and excellent wear/scratch resistance, suitable for modern minimalist styles.

2.Electrophoretic coating: Creates a smooth, mirror-like surface with uniform and vivid color, offering better moisture resistance.

3.Powder coating: Enables a wide range of color choices, with matte or textures that can match different decoration styles.

When purchasing, check for scratches or bubbles on the surface and feel the smoothness by touch—high-quality aluminum alloy handles should have no obvious defects.

Style Matching – Choosing Aluminum Handles for Different Home Décor

The design of aluminum alloy handles should echo the furniture style and spatial tone: 1.Modern minimalist style: Choose handles with straight lines and narrow edges (e.g., single-rod or invisible embedded styles) in neutral colors like silver, black, or gray to highlight a concise spatial feel. 2.Light luxury style: Opt for handles with metal wire-drawing textures in gold or bronze, with double-bend angles or curved designs to add sophistication. 3.Pastoral/Nordic style: Try matte white or wood-wrapped aluminum alloy handles with rounded edges for a warm and soft look.

Size Specifications – Selecting the Right Aluminum Cabinet Handle Length

1.For cabinet doors under 80 cm in height: Choose handles 12–16 cm in length.

2.For cabinet doors 80–120 cm in height: 16–22 cm handles are suitable.

3.For large cabinet doors over 120 cm: 22–30 cm long handles are needed to ensure balanced stress.

4.For drawers: Select handles with a length proportional to the drawer width (usually about 1/3 of the drawer width) for both aesthetics and ease of use.

Detail Design – Improving User Experience with Aluminum Handles

Small details significantly impact the usability of aluminum alloy handles: 1.Mounting plates: Handles with mounting plates enhance stability by increasing the stress area, ideal for heavy cabinet doors. 2.Invisible design: Embedded handles reduce collision risks, making them perfect for families with children. 3.Hole spacing: Ensure the handle’s hole spacing matches pre-drilled holes in furniture (common standards: 64mm, 96mm, 128mm); choose adjustable styles for special sizes. 4.Comfort: Prioritize handles with rounded edges and comfortable grip—avoid sharp edges or overly thin grip areas.

Conclusion – The Perfect Balance of Functionality & Aesthetics

By mastering these purchasing points, aluminum alloy handles can become “invisible heroes” in your home, exerting long-lasting practical value while enhancing the overall beauty of the space through detailed design, achieving a perfect balance between functionality and decorativeness.